Instrument introduction:

The crystal size of X-MaxN ranges from 20 mm2 to nanometer material suitable for micrometer analysis. A total of 150 mm2 options are available in four. Especially the 150 mm2 is the largest detector in the crystal area today, and the analysis speed is at least two times of that of the ordinary detectors.

Overview

• The detector crystal sizes are 150 mm2, 80 mm2, 50 mm2, 20 mm2, respectively

• Regardless of the crystal size, the resolution of X-MaxN is consistently good - and conforms to the standard ISO15632:2012

• Regardless of the size of the crystal, the size of the outer tube and the position of the electron microscope in the spectrometer are exactly the same. Under the same conditions, the increase of the counting rate can only be attributed to the increase of the crystal size

• Powerful low energy end analysis, all crystal area energy spectrometers are guaranteed to start with Be

• As with the previous generation of X-Max, both SEM and FIB use the same interface

• Regardless of the size of the crystal, excellent performance remains constant

• The crystal area of X-MaxN is 20mm2, 50mm2, 80mm2, and, 150mm2 - 150mm2 is the largest energy spectrometer in the crystal area

• Because of its unique external FET FET design, the resolution of X-MaxN is completely unaffected by the change of crystal area, and it always has excellent low energy detection performance

• The same size of the detector means that the counting rate is only related to the crystal area under the same conditions

• All spectrometers with a good crystal area have excellent energy resolution

• Superior low energy end analysis capabilities ensure that all sizes of spectrometers can detect Be elements

• The use of a large energy spectrometer means that:

• There is sufficient counting rate under low beam

• Realize the visibility and accuracy of the image as high as possible

• There is no need to change the conditions of SEM for spectral analysis

• In the same beam, the counting rate is greatly improved

• Shorten acquisition time

• Statistically higher

• Energy spectrum analysis to achieve the small spot

• Improving the spatial resolution of spectrum detection

• As far as possible, the advantages of high resolution electron microscopy are demonstrated

• The larger the crystal area, the higher the efficiency of X- ray counting

Under the same conditions, the larger the crystal area is:

• Work that took a few minutes to finish before, now only takes a few seconds - the surface / line distribution is easier to get

• The acquisition time is the same, which can greatly improve the analysis accuracy and statistics

• Large area energy spectrometer -- rapid acquisition of all microscopic analyses

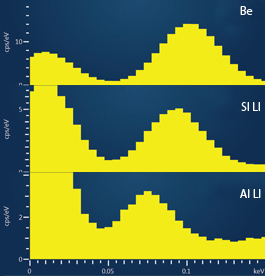

Excellent low energy end analysis performance

X-MaxN makes great optimizations for the analysis of low energy end elements - no matter what size, has demonstrated superior low energy end analysis performance unprecedented

• All sizes of spectrometers can guarantee the detection of Be, and the surface distribution of SiLI peaks can be obtained

• The large area energy spectrometer has excellent low energy end analysis performance

• Excellent spatial resolution

High spatial resolution, X ray expansion region is smaller

• Large area energy spectrometer can capture X- ray at low acceleration voltage and low beam

• The characteristics of nanometer scale can better be detected

• Ultra large energy spectrometers make advanced nanoscale analysis possible

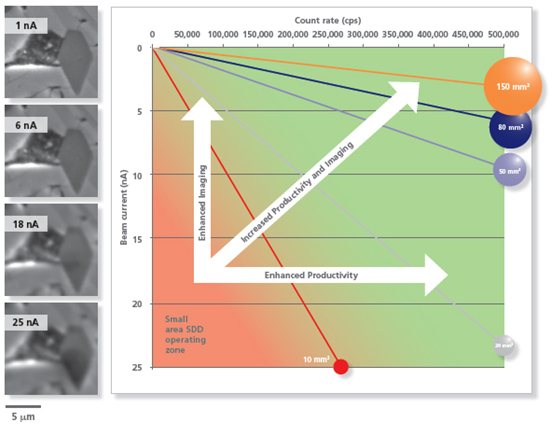

• Where is the advantage of a 150 mm2 spectrometer over a small crystal area?

As an example. The acceleration voltage is 20kV, and when the beam is less than 2nA, the 150 mm2 spectrometer can output 200000 counts per second. When using a 10 mm2 spectrometer, it will take nearly 20nA to achieve the same counting rate.

• The following figure shows typical counting rates under different beam currents. When the pure Mn is analyzed under 20kV, the detector has an angle of detection of 30 degrees and is 45mm away from the sample. Using a large area energy spectrometer, the counting rate can be greatly increased without increasing the beam. That is to say, in low beam flow, enough counts can be obtained while ensuring high spatial resolution and low radiation damage. On the left shows the beam to increase the influence and improve the quality of image.

Influence of beam on the analysis of nanomaterials

• When using a small energy spectrometer with a small crystal size, a high beam is needed to satisfy the sufficient counting rate, but the spatial resolution is impaired. Super large area energy spectrometer X-MaxN 150 can obtain enough counting at low beam or high spatial resolution, so it can be successfully detected and analyzed.

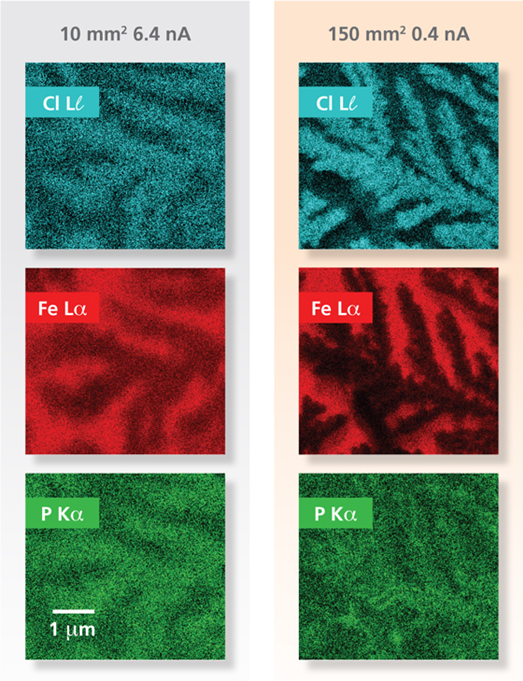

Image above: the X- - ray distribution of nanostructures under 5kV. At the same time, the 150mm2 spectrometer requires a lower beam density, which means that the spatial resolution is high enough to distinguish the nanometer scale changes and greatly reduce the radiation damage of the sample. In contrast, the 10mm2 spectrometer requires a higher beam, which can seriously damage the spatial resolution and blur the area distribution image.

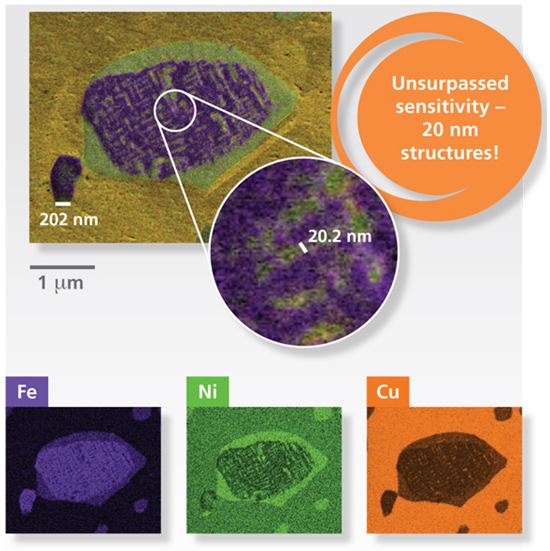

Image above: at 0.2 nA and 3 kV, the nanostructures in the memory alloy are analyzed using a 150 mm2 X-MaxN spectrometer. It can be observed that the FeLa, NiLa and CuLa peaks show differences in the nanostructure distribution, and the smallest can distinguish the structure of 20nm width.